Dense Phase Pneumatic Conveyor

The Best Way To Convey, Gently, Your Products.

Dense Phase Pneumatic Conveying Systems

The dense phase pneumatic conveying system ensures low-speed material transport with a minimal air-to-product ratio, reducing energy consumption and preserving product integrity compared to other methods.

This system maintains granule integrity, providing efficient, cost-effective conveying with minimal air consumption.

The fully enclosed design and absence of moving parts enhance safety and hygiene, making it ideal for industries requiring contamination-free handling such as food, pet-food, chemical and pharmaceutical products.

Also, High-quality components and an innovative design minimize maintenance costs.

The outlet unit made in high cast iron with a carbonitriding thermal treatment, a special lateral, lower and inner advanced air fluidization systems ensures durability and optimized transport efficiency.

The system is available in carbon steel or stainless steel (AISI 304 or AISI 316), with food-grade finishes and components and ATEX classified.

Additionally, configurations include:

- Dense phase version – with a pipeline cleaning cycle after each batch.

- Extra-dense phase version – with full-pipeline operation.

- HP version – High-Performance designed for long-distance transport and high hourly capacities.

+ Key Features of Our Dense Phase Pneumatic Conveyors

High Efficiency and Low-Consumption Systems

Our dense phase pneumatic conveyors are designed to maximize energy efficiency, significantly reducing operational costs by operating at low velocities and minimizing air consumption.

Gentle Handling of Fragile and Abrasive Materials

Specifically engineered for the gentle transport of fragile and abrasive bulk materials, our systems minimize wear and tear, reducing product loss and extending equipment life.

Low-Velocity Transport for Precise Flow Control

Designed for low-velocity material transport, our dense phase pneumatic conveyors provide precise and controlled material flow, reducing the risk of material degradation and ensuring optimal handling.

Dust-Free and Contaminant-Free Transport

Fully enclosed pneumatic systems ensure a dust-free environment, preventing material spillage and contamination. Ideal for industries requiring clean and safe material handling.

OUR SOLUTIONS

GA TYPE PNEUMATIC CONVEYORS

GA Type main feature is the inlet butterfly valve.

This is the mostly used solution for non-abrasive products and in general in sectors like food, pet-food, plastic, chemical and pharmaceutical sectors.

The sizes go from 24 ltrs up to 4.000 ltrs vessels capacity.

These conveyors can be supplied both in dense phase with a cleaning cycle after each launch or in extra-dense phase for fragile products or products’ mixing.

They can also be equipped on load cells for the material weighing before transport or supplied in Atex classified version. Solution for non-abrasive products.

+ Key Benefits

Available for food and pharmaceutical transport with food grade components

Optional in Atex classified version

Extra dense phase for fragile products and products mixing

Optional on load cells for products’ weighing

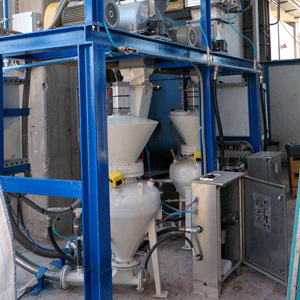

GA-AA TYPE PNEUMATIC CONVEYORS

GA-AA type is a special weighing conveyor type.

In the GA-AA conveyor type the machine is equipped with an inlet butterfly valve and a central load cell which weighs the product loaded inside the vessel before the transport.

The pneumatic conveyor’s vessel is hanged on the supporting structure and the accuracy of the weigh is greatly increased.

In addition, the pneumatic panel is installed on board the supporting structure for a more compact solution.

+ Key Benefits

Special weighing conveyor

High weigh accuracy

On board pneumatic panel

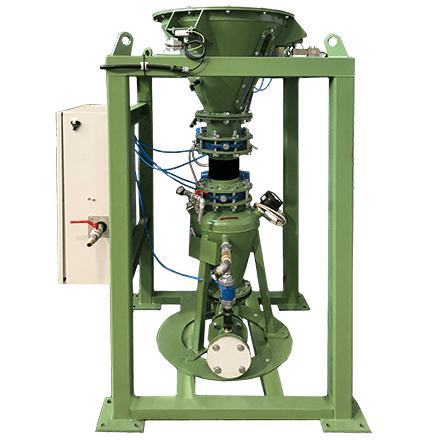

GC TYPE PNEUMATIC CONVEYORS

GC Type is especially designed for abrasive products transport. Thanks to a unique inlet "Cone Valve" made in Ni-Hard cast iron the wearing problems are widely reduced compared to the standard solution with inlet butterfly valve.

This solution is particularly suitable for materials like silica, silica sand, glass beads or glass sand, quartz sand transport and so on.

The preloading hopper can be supplied with one or two flanged inlets depending on the application needs. Available sizes go from 24 ltrs up to 1500 ltrs vessels capacity and both dense (with cleaning cycle after each launch) and extra-dense (with full pipeline) versions are possible.

These conveyors can be supplied in version for products with high temperature, equipped on load cells for the material weighing before transport or in Atex classified version.

+ Key Benefits

Pre-loading hopper with one or two products’ inlets

Extra dense phase for highly abrasive or fragile products or for products mixing

Optional for products with High Temperature

Optional on load cells for products’ weighing Optional in Atex classified version

Especially studied Ni-Hard cast iron inlet cone valve

Solution for abrasive products

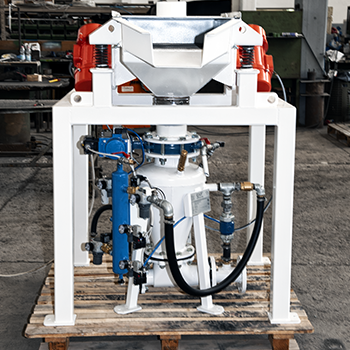

GA COMBO TYPE PNEUMATIC CONVEYORS

GA-Combo type is a compact version of the “GA type”, specifically designed to reduce both installation costs and required installation space. This modular and robust conveyor system is ideal for handling powders and grains.

This conveyor is equipped with both pneumatic and electrical panel installed on board the machine. It's commonly installed under filters outlets, presses or manual bag discharging hoppers, making it the perfect solution for all applications which require simplicity and reliability in a compact machine.

The conveyor can also be supplied with wheels, allowing for easy mobility and flexible use across different workstations.

+ Key Benefits

Compact GA type version

Pneumatic and electrical panels installed on board

Easy installation under filters, presses or manual bag discharging hoppers

Optional feet on wheels for easy movement.

STAINLESS STEEL PNEUMATIC CONVEYOR

STAINLESS STEEL FINISHING

2B finishing is obtained starting with a 2D finishing and adding a skin-pass rolling, which gives it a milky grey appearance. It has a much higher reflectivity than the 2D finishing, which gives it a less matt and more clean appearance.

2R FINISHING - BRIGHT ANNEALED

2P FINISHING

2P finishing is obtained starting from a very raw steel finishing that is then polished with rotating cloth brushes impregnated of extra-fine texture pastes. The result is a shiny and reflective surface completely lacking of unidirectional lines and with a perfect mirror-like finishing.

Features

Vessels construction in stainless steel AISI 304 and AISI 316

Stainless steel components

Available capacity from 24 to 3.000 lt

Compete with stainless steel electro-pneumatic control panel in box

Available with FDA e MOKA certification

Air injection cyclonic system for vessels' cleaning

Special applications

The in-house production of the vessels and of the complete machine allows a high level of control on the products’ quality and also a high level of products’ customization.

GVF Impianti produces on request pneumatic conveying systems for special applications such as for the transport of products with high temperature which may also need the addition of heat tracing and insulating systems, both for pneumatic conveyors type GA and GC (for abrasive products).

Additionally, all the machines can be made in accordance with Atex 2014/34/UE Directive classification II 3D or equipped with weighing systems on load cells.

We Make and Test in-house our Vessels.

AUTOMATION AND SOFTWARE

The electrical panel is equipped with a PLC for the pneumatic transport parameters management and with an operator interface that could differ depending on the pneumatic conveyors’ sizes and versions.

Contact us now for a personalized quote and optimize your production process!

Phone

Address

Contact Us