gLASS RECYCLING PLANS

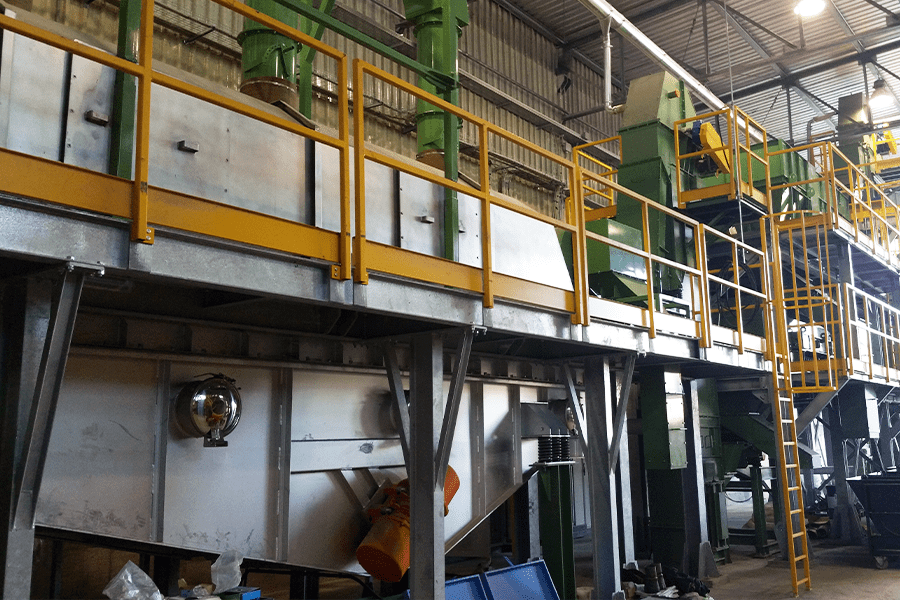

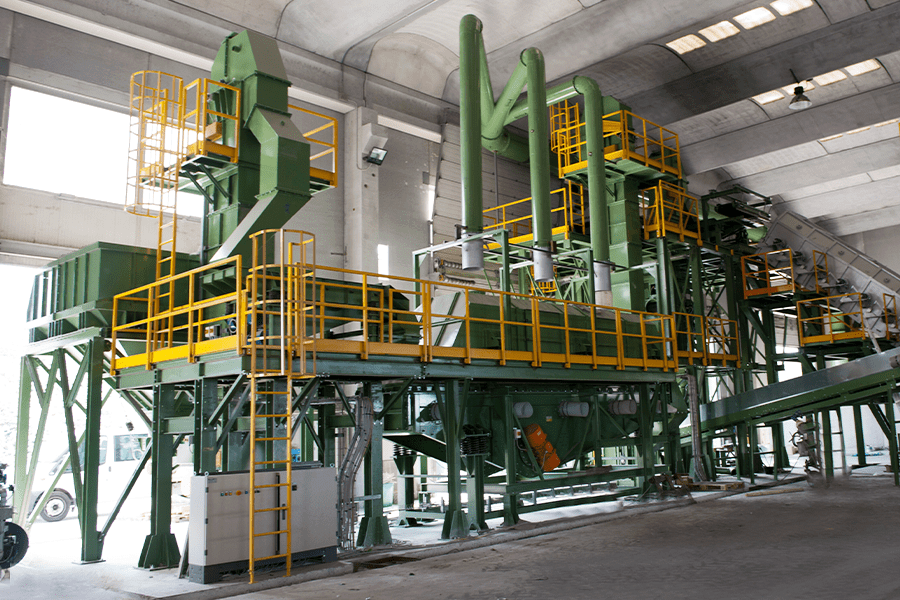

glass recycling plant

Glass sand plant

How to Transform the Glass Waste in a Product Ready for Melting

Features

Reduction of Lead Content

Reduction of lead content

The inlet material is pre-treated and selected in order to remove the presence of lead inside the final product.

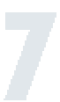

Organic parts removal

Thanks to a complex system of specifically-designed machines, the product is dried and cleansed of its organic components.

Controlled grain size

The final product is composed by glass sand which has a totally controlled and stable grain size.

Totally dry process

The first and unique totally dry process. This allows to avoid water usage and water treatment-related problems, such as the need of plants for water purification. The lack of humidity inside the final product allows the storage of the material into silos and the direct loading on trucks.

Low energy consumption

A very complex system for energy recovery allows to greatly reduce the energy consumptions in order to minimize operational costs.

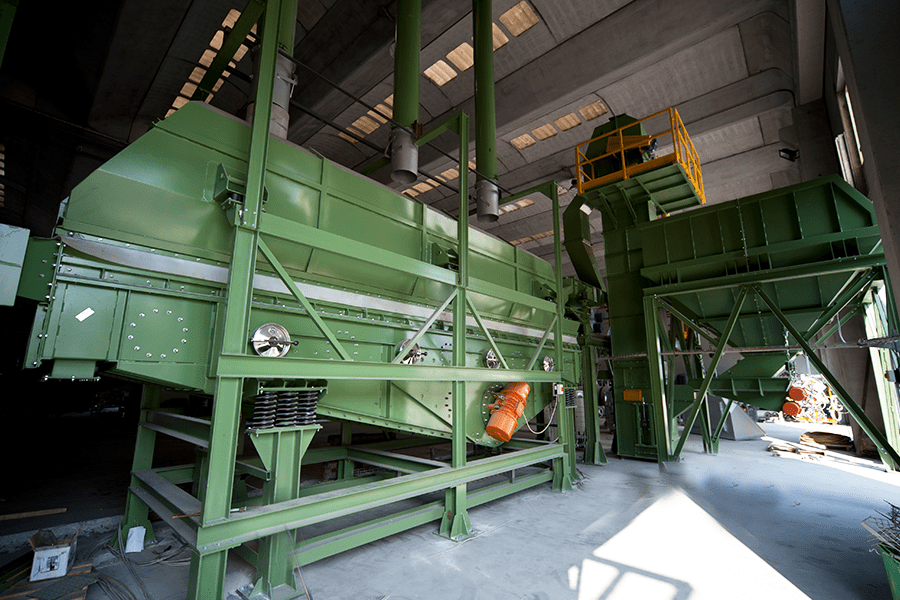

Fully automated plant

The entire system is fully automated and requires only supervision activities. This is the reason for the plant’s high efficiency and profitability.

The plant is completely automatic. All processes are done without requiring men for the selection activities or for the functioning of the entire plant. Only supervision activities are required. This feature allows the reduction of human resources related costs, and increases the profitability and the efficiency of the plant.

Environmental protection

We have designed the plant in order to combine low energy consumption and air pollution control, reducing the environmental impact to a minimum.

We have designed the plant in order to combine low energy consumption and air pollution control, reducing the environmental impact to a minimum.

The recycling process of products, allows the protection of scarce resources and raw materials. For this reason the glass recycling is itself a process that helps to protect the environment and its resources.

GVF Impianti combines the usefulness gained from the recycling, with low energy consumption, no water usage and air pollution control.

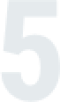

Fluid bed dryer

The vibrating fluid bed dryer is used to dry the inlet material in the plant, and is produced with capacities up to 50 ton/h.

The dryer is composed by a lower hot air inlet plenum and by a series of sealed drawers, which direct the material.

The machine is equipped with a continuous working temperature adjusting system.

With a group of adjusting valves controlled by continuous engines, is then guaranteed the correct power supply, depending on the humidity’s quantity present in the material.

Phone